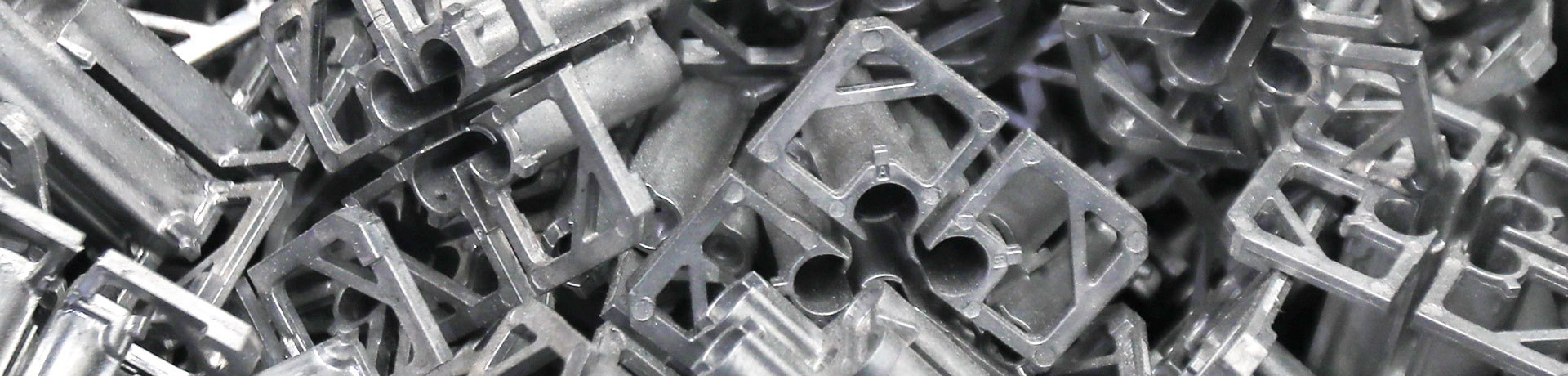

Die castings 5

Category:

Detail

The control of the surface temperature of the die casting mold is very important for the production of high-quality die castings. Uneven or inappropriate mold temperature will also lead to unstable casting size, ejection casting deformation during the production process, resulting in defects such as thermal pressure, adhesive mold, surface depression, shrinkage holes and hot bubbles. When the mold temperature is different, it has different degrees of influence on the variables in the production cycle, such as filling time, cooling time and spraying time. The design of die castings must consider seven aspects: wall thickness of die castings, casting rounding and demolding slope of die castings, stiffeners, minimum distance from the casting holes and holes on the die castings to the edge, rectangular holes and grooves on the die castings, inserts in the die castings, and the processing allowance of the die castings.

Previous

Next

Previous

Next

Other Products

I Want to Consult